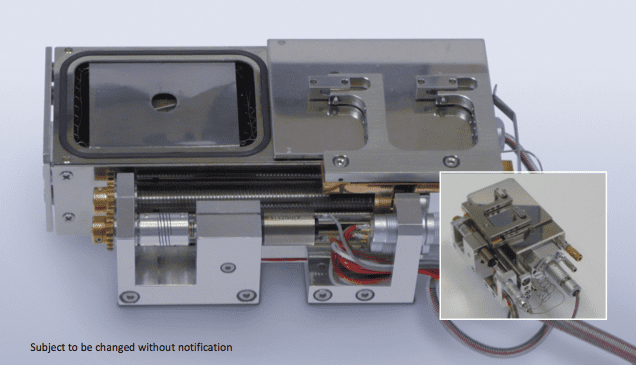

Heating module for MEB motorized stage.

Module compatible with corrosion tests or heating tests in a gas atmosphere.

When the temperature is maintained below 600°C, this module is compatible with corrosion tests or heating tests in a gas atmosphere.

It is possible to have an optional needle valve positioned on the mechanical interface of the MEB in order to inject a small quantity of gas into the module during heating tests. The heating chamber where the sample is placed can be closed with a motorized cover to protect the SEM during high temperature experiments.

Very high temperature experiments

The central part of the sample holder is an encapsulated ceramic resistor which generates the heating. The object holder is available with different shapes (flat, dome, etc.). Flat samples can be 10 x 10 mm in size and are held by tungsten spring clips. The design is intended to minimize the electric field that could affect imaging.

This heating module can be used as a transfer capsule between a glove box and an MEB thanks to its sealing. It is thus possible to protect the samples from humidity or oxygen.

The system includes the mechanical interface with connections suitable for the MEB and also the closed loop water circulator for module cooling.

Temperature controller

Integration of the module into the MEB

The heating module is mounted in the SEM as a large sample with a dovetail system. Most MEBs are compatible with this heating module. A closed loop water circulator is also supplied with the module.

Gas heating below 600°C (Option)

This 1,050°C module with vacuum transfer system goes beyond these experimental conditions and allows, thanks to a small valve, to inject gas into the hermetic chamber to create a particular gas environment or a corrosive environment.

The gas inlet is precisely controlled by a needle valve located on the mechanical interface of the MEB (cable passage integrating the valve). A tube (stainless steel capillary) allows the gas to be injected into the chamber of the heating module. The chamber can be opened and closed tightly by a motorized mechanism.

Heating module

The heating element incorporates an internal reflection shield, fixed with a minimum contact surface in order to keep the heat flow level with the sample surface. After one hour of heating, it is recommended to interrupt heating for 15 minutes to preserve the environment of the sample and to protect the detectors from overheating.

There is a version of the heating module compatible with EBSD.

The module is equipped with closed-loop water circulator cooling for long experiments.

Different sample attachment methods are possible such as classic SEM supports, crucibles, etc.

Heating module for MEB for a long experience up to 1,050°C and up to 600°C in a gaseous environment.

Supplied with the flange to be installed on a port of the MEB (to be defined with the 'user the ports available on the MEB).

Module specifications

- Dimension of the heating module: 65 x 55 x 38 mm

- Weight: 1 kg.

- Maximum sample size: 10 x 10 x 2 mm

- Maximum heating rate: 5°C/s max.

- Temperature sensor: NiCr-Ni.

- Temperature range: Ambient to 1050°C.

- Temperature stability: +/- 1°C.

Controller specifications

- Dimension: 295 x 320 x 125 mm

- Weight: 7 kg.

- Input voltage: 115/230V, AC 50-60Hz.

- Power consumed: 250W maximum.

- Heating voltage: 0-30V, DC

- Heating current: 5A

- Interface: RS 485