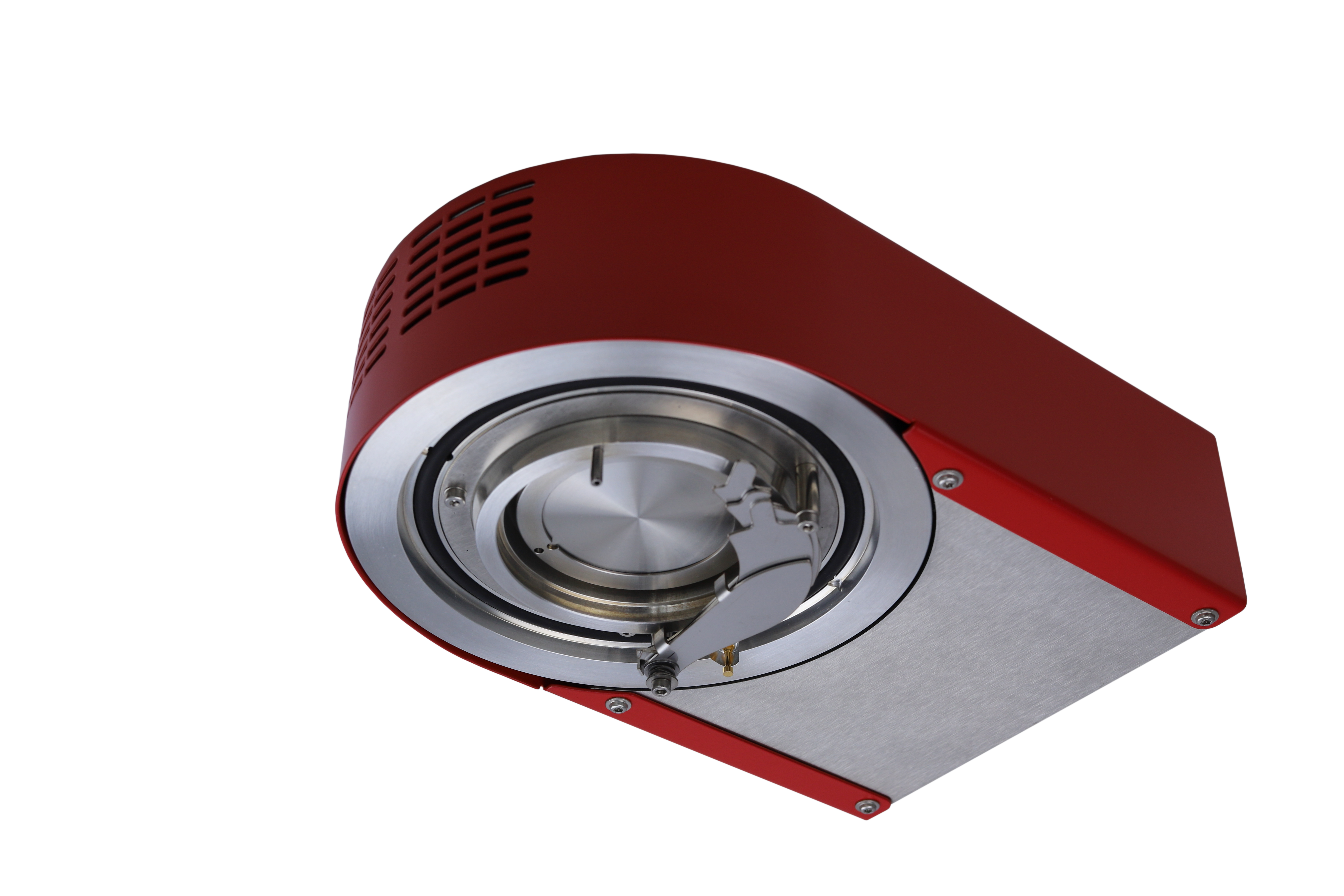

High compact vacuum coating system

The CCU-010 high vacuum sputter and carbon coater was designed for the highest demands in the field of sample preparation. Premium components and a smart design allow excellent results in ultra-high-resolutionapplications.

The device is a compact, fully automatic sputter coater and/or carbon coater. The CCU-010 HV base unit pumping system is totally oil-free and includes a high performance turbo pump and diaphragm backing pump, both internally located, giving the coater a very small footprint (no cumbersome rotary pump and vacuum lines). It is a mini sputter coater size wise with big potential.

The use of an oil-free, pumping system reduces contamination or defects in the coating to a minimum. The device can be kept under vacuum when switched off. This efficiently protects the system from dust and humidity and creates a fast pumping speed and proper vacuum conditions for high-quality coatings.

Head for carbon deposition by carbon wick (braid)

Patented system for winding carbon bits (2 meters) on a rotating mandrel for automated loading without manual reloading after each carbon deposit

Up to 50 sprays without changing the carbon wick

Automatic mechanical shutter

For use with 1 or 2 meter carbon bits.

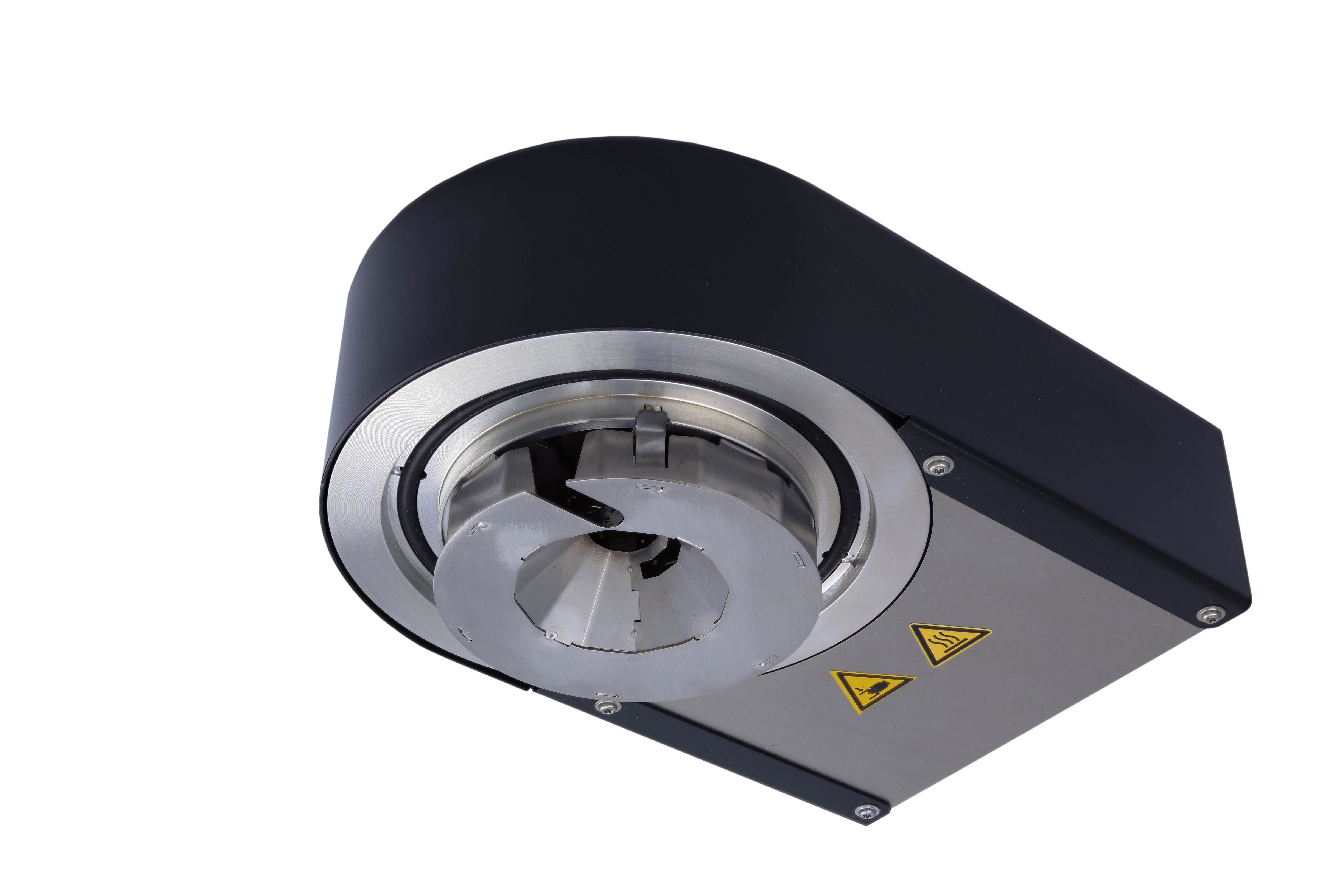

Head for metallization by cold cathode sputtering

Simply interchangeable head in seconds

Magnetron type head for high efficiency metal deposition

Uniformity of metal deposits better than: ± 2.5% (depending on location and height adjustment within the chamber)

Allows deposits of controlled thickness between 1 nm and a few µm (2 to 3 µm)

Checking the Argon pressure value in the chamber

Auto shutter

Metal cathode temperature and layer thickness control system

Size of metal targets: 54 mm Ø x 3 mm thickness

Supports metal targets of the following elements: Ni, Al, Pt, Au, Cu, Ag, Au/Pd, Fe, Co, Cr, ITO, W, C, Ti, Pt/Ir, Pt/Pd,Ir.